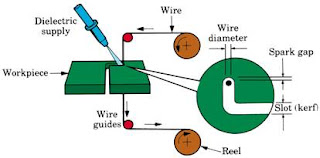

This process is also known as 'Travel-Wire EDM'.In this machining,the tool used is copper or bras wire.A hole is pre-drilled on the workpiece through which we pass the electrode (Copper wire).The copper wire is stretched between two wheels and continuously travelling from source spool.the take up spool.Principle is same that of the EDM.the wire is made cathode and the workpiece is made anode.the work piece is mounted on a CNC table,movement of which is programmed.The dielectric fluid is spayed to the cutting zone.the usually used dielectric fluid is De-ionised water.

Advantages:

Using this method,we can cut complex 2D shapes from the workpiece.

Advantages:

Using this method,we can cut complex 2D shapes from the workpiece.

No comments:

Post a Comment